Learn the fundamentals of PVC electrical conduit installation with this essential guide․ Discover how to safely and efficiently install PVC conduit for protecting electrical wiring in modern systems․

Importance of PVC Conduit in Modern Electrical Systems

PVC conduit plays a vital role in modern electrical systems due to its durability, corrosion resistance, and flexibility․ It provides a safe and reliable pathway for electrical wiring, protecting cables from environmental factors like moisture, chemicals, and mechanical damage․ PVC conduit is lightweight, easy to install, and offers excellent insulation properties, making it ideal for both underground and surface-mounted applications․ Its resistance to corrosion ensures long-term performance in harsh conditions, reducing the risk of electrical failures․ Furthermore, PVC conduit systems are cost-effective and adhere to various electrical codes and standards, ensuring compliance and safety in residential, commercial, and industrial settings․ Its versatility and reliability make it a preferred choice for modern electrical installations․

Overview of the Installation Process

The installation of PVC electrical conduit involves a systematic approach to ensure safety, efficiency, and compliance with electrical codes․ The process begins with planning and design, including cable sizing and conduit routing to meet specific electrical requirements․ Next, materials and tools are prepared, such as PVC conduit, fittings, cutters, and bending equipment․ The site is then readied, ensuring a clean and accessible work area․ Cutting, bending, and joining the conduit are performed with precision to maintain integrity and proper connections․ Finally, the conduit is installed, either underground or surface-mounted, followed by inspection and testing to ensure code compliance and functionality․ This structured process guarantees a reliable and durable electrical system․

Materials and Tools Required

Essential materials include PVC conduit, fittings, couplers, and sealants․ Tools like hacksaws, PVC cutters, bending equipment, and safety gear are necessary for efficient and safe installation․

PVC Conduit Types and Specifications

PVC conduit is available in various types, including Schedule 40, Schedule 80, and flexible PVC conduit․ Schedule 40 is the most common for general applications, while Schedule 80 offers thicker walls for higher pressure and durability․ Flexible PVC conduit is ideal for tight spaces and applications requiring bends without cracking․ Conduit materials must meet standards like NEMA TC-2 and TC-3 for rigidity and safety․ Sizes range from 1/2″ to 6″ in diameter, with specific applications depending on wire size and load requirements․ Always ensure conduit meets local electrical codes and is compatible with fittings and cables for reliable performance and safety․

Cutting Tools and Accessories

Proper cutting tools are essential for clean, precise cuts in PVC conduit․ Common tools include hacksaws, fine-toothed handsaws, or dedicated PVC conduit cutters․ For conduit over 2 inches in diameter, a miter box or saw guide ensures square cuts․ After cutting, deburr the edges using a utility knife, file, or deburring tool to prevent damage to wires and ensure smooth installation․ Accessories like cutting guides or miter boxes help maintain accuracy, while safety gear such as gloves and goggles protects against injuries․ Always use tools designed for PVC to avoid cracking or shattering the material․ Proper cutting techniques are critical for maintaining conduit integrity and ensuring safe, reliable electrical connections․

Bending and Joining Equipment

For bending PVC conduit, heat guns or portable heaters are commonly used to soften the material, allowing for precise bends without cracking․ Conduit benders or bending shoes are essential for creating smooth, kink-free curves, especially in tight spaces․ When joining sections, PVC primer and cement are critical for creating strong, leak-proof connections․ Couplers, adapters, and elbow fittings are used to connect conduit sections securely․ Proper bending and joining techniques ensure the integrity of the electrical system, preventing damage from environmental factors and maintaining reliable conductivity․ Always follow manufacturer guidelines for equipment usage to achieve durable and compliant connections․

Safety Precautions and Best Practices

Ensure proper use of PPE, follow NEC guidelines, and maintain a clean worksite to minimize hazards during PVC conduit installation․

Personal Protective Equipment (PPE)

Wearing proper Personal Protective Equipment (PPE) is crucial during PVC conduit installation․ This includes safety glasses, gloves, a hard hat, and steel-toe boots to protect against debris and electrical hazards․ Ensure all PPE meets industry standards to guarantee safety and compliance with regulations; Proper eye protection prevents injuries from flying particles during cutting or drilling․ Gloves provide grip and safeguard hands from sharp edges and chemicals․ A dust mask is recommended when cutting or sanding materials to avoid inhaling harmful particles․ Always maintain a clean and organized worksite to reduce tripping hazards and ensure efficient workflow․ Adhering to PPE guidelines is essential for a safe and successful installation process․

Worksite Safety Guidelines

Ensuring a safe working environment is critical during PVC conduit installation․ Always secure the worksite to prevent unauthorized access and potential accidents․ Properly store tools and materials to avoid tripping hazards․ Ensure all electrical systems are de-energized before starting work, and verify this with a voltage tester․ Use ladders and scaffolding safely, adhering to height safety protocols․ Keep the area well-ventilated, especially when using adhesives or cutting materials․ Regularly inspect tools and equipment for damage or wear․ Clearly mark underground conduit locations to prevent accidental damage during digging․ Ensure all team members are trained in proper lifting techniques to avoid injuries․ Maintain a first aid kit on site and have an emergency response plan in place․ Adhere to local safety regulations and building codes to ensure compliance․

- Secure the worksite and restrict access to authorized personnel․

- De-energize all electrical systems before commencing work․

- Use proper lifting techniques to prevent injuries․

- Ensure proper ventilation when cutting or gluing conduit․

Emergency Procedures

In case of emergencies during PVC conduit installation, it’s crucial to have a well-prepared response plan․ Start by evacuating the area and ensuring everyone’s safety․ For electrical shocks, immediately disconnect the power supply and provide first aid if necessary․ In the event of a fire, use a fire extinguisher rated for electrical fires and evacuate the premises․ If someone is injured, administer first aid and call for medical assistance promptly․ Keep emergency contact numbers accessible, including the fire department and medical services․ Ensure all team members are trained in basic first aid and emergency procedures․ Regularly inspect fire extinguishers and ensure they are easily accessible․ Maintain a first aid kit on site and update it periodically․ Having a clear emergency response plan can prevent minor incidents from escalating into major crises․

- Evacuate the area immediately in case of emergencies․

- Disconnect power supply in case of electrical shock․

- Use appropriate fire extinguishers for electrical fires․

- Provide first aid and seek medical help when needed․

Planning and Design Considerations

Proper planning ensures efficient and safe PVC conduit installation․ Assess load requirements, plan conduit routes, and ensure compliance with electrical codes and standards for optimal performance․

Cable Sizing and Load Calculation

Accurate cable sizing and load calculation are critical for ensuring safe and efficient electrical systems․ Determine the required ampacity based on the connected load and select cables that meet or exceed this demand․ Consult NEC tables and factors to account for insulation type, ambient temperature, and the number of wires in the conduit․ Proper sizing prevents overheating, voltage drop, and potential system failure․ Use cable fill charts to verify the maximum number of cables that can be installed in the conduit without damaging insulation or violating safety standards․ Always ensure compliance with local electrical codes and regulations to guarantee reliability and safety in the system design․ Correct sizing is essential for long-term performance and compliance․

Conduit Routing and Layout

Proper conduit routing and layout is essential for a safe and efficient electrical system․ Plan the conduit path to minimize bends and avoid obstacles, ensuring compliance with local codes․ Use sweeps or elbows instead of sharp bends to maintain cable integrity․ Secure conduits every 3-4 feet and label them clearly for identification․ Ensure the layout adheres to building plans and environmental conditions․ Adjust routes to accommodate future expansions or modifications․ Proper routing prevents damage, reduces installation time, and ensures long-term reliability․ Always verify the layout against approved designs before proceeding with installation․ Correct routing is vital for system performance and safety․

Installation Steps

Follow a systematic approach: plan the layout, cut conduit to size, bend as needed, and secure it․ Ensure all connections are tight and properly sealed for safety and durability․

Cutting and Deburring PVC Conduit

Cutting PVC conduit can be done using a hacksaw, fine-toothed handsaw, or specialized PVC conduit cutters․ For conduit with diameters over 2 inches, use a miter box or saw guide to ensure straight, square cuts․ After cutting, deburr the edges using a utility knife, file, or deburring tool to remove sharp edges and burrs․ This step is crucial to prevent damage to wires during installation and ensure smooth connections․ Always wear safety gloves and eyewear during cutting and deburring․ Properly prepared conduit ends ensure secure fittings and prevent leaks or electrical issues․ Remove any PVC tape or protective coverings from the ends before proceeding with further installation steps․

Bending PVC Conduit

Bending PVC conduit requires careful techniques to maintain its structural integrity․ For smaller diameters, manual bending is feasible, while larger sizes may need heat guns or bending irons․ Preheating the conduit to 200°F–250°F softens the material, allowing for precise bends without cracking․ Use a bending template or guide to achieve the desired angle․ Avoid overbending, as it can cause kinking or weakening․ After bending, allow the conduit to cool before handling to prevent warping․ Always wear protective gloves and eyewear during this process․ Proper bending ensures smooth wire installation and maintains the system’s durability․ Follow manufacturer guidelines for heating times and temperatures to avoid damaging the PVC material․

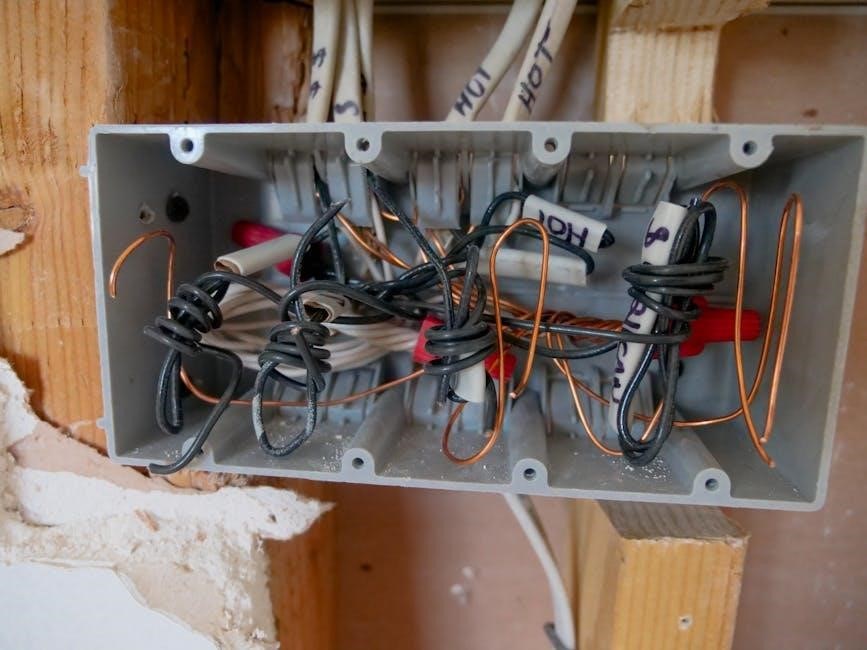

Joining and Coupling Conduit Sections

Joining and coupling PVC conduit sections is a critical step for ensuring a secure and leak-proof connection․ Start by cutting the conduit to the required length using a PVC cutter or hacksaw, ensuring a clean, square edge․ Deburr the cut ends to prevent damage to wires․ Apply a primer to the ends of the conduit and coupling, followed by a thin layer of PVC cement․ Quickly assemble the pieces, ensuring proper alignment․ Hold the joint for a few seconds to allow the cement to set․ For underground or high-stress applications, use couplers or fittings designed for added durability; Properly joining PVC conduit sections ensures long-term reliability and prevents environmental factors from compromising the electrical system․ Always follow manufacturer instructions for primer and cement application to guarantee a strong bond․

Underground Installation

Underground PVC conduit installation requires careful planning and execution to ensure durability and compliance with safety standards․ Begin by trenching to the required depth, typically 12 inches or more, depending on local regulations․ Use Schedule 40 PVC conduit for underground applications due to its thickness and resistance to environmental factors․ Ensure the conduit is properly coupled and sealed to prevent water ingress․ For rocky or unstable soil, consider using conduit with additional protective sleeves․ After laying the conduit, inspect it thoroughly before backfilling to ensure no damage or defects․ Properly secure joints and couplers to maintain system integrity․ Always consult local electrical codes and regulations to ensure compliance and safety during underground installations․

Surface-Mounted Installation

Surface-mounted PVC conduit installation is ideal for exposed areas, offering easy access and visibility․ Begin by planning the layout to ensure the conduit runs neatly and securely․ Use heavy-duty rigid PVC conduit for surface mounting, as it is designed to withstand environmental exposure․ Secure the conduit to walls or ceilings using approved brackets or clips, ensuring proper spacing and alignment․ Seal all joints and couplers with PVC cement and primer to maintain system integrity․ For outdoor installations, apply UV-resistant conduit or paint to protect against sunlight․ Avoid tight bends and ensure proper support to prevent sagging․ Always follow local electrical codes and manufacturer guidelines for a safe and durable installation․ Surface-mounted PVC conduit is a practical solution for modern electrical wiring needs․

Inspection and Testing

Inspect PVC conduit for damage, leaks, or improper joints․ Test conduit integrity using pressure checks or visual inspections․ Ensure compliance with safety standards and codes․

Visual Inspection of Conduit Runs

A thorough visual inspection of PVC conduit runs is essential to ensure system integrity․ Check for cracks, damage, or misalignments in the conduit․ Verify that all connections, couplers, and fittings are securely fastened and free from gaps․ Ensure proper sealing of joints to prevent moisture ingress․ Look for signs of environmental stress, such as discoloration or warping, which may indicate exposure to heat or chemicals․ Confirm that conduit routing adheres to approved designs and local codes․ Pay special attention to bends and joints, as these are common failure points․ Use a checklist to systematically evaluate each section of the conduit run․ Any defects or irregularities must be documented and addressed before final approval․ Proper visual inspection ensures long-term reliability and safety of the electrical system․

Testing Conduit Integrity

Testing conduit integrity ensures the PVC electrical system is leak-proof and durable․ Conduct pressure testing by sealing the conduit ends and applying air pressure with a gauge․ This identifies any leaks or weak points in joints or fittings․ Use approved testing methods to verify the conduit’s ability to withstand environmental conditions․ Perform continuity tests to ensure proper electrical grounding․ After visual inspections, integrity testing confirms the system’s reliability․ Address any defects or leaks promptly to maintain safety and compliance․ Regular testing prevents future issues and ensures long-term performance․ Adhere to local codes and standards for testing procedures to guarantee a secure electrical infrastructure․

Verification Against Codes and Standards

Verification against codes and standards ensures PVC electrical conduit installations meet safety and regulatory requirements․ Compliance with National Electrical Code (NEC) and local standards guarantees proper installation and safety․ This includes correct conduit sizing, material specifications, and approved fittings․ Regular inspections and documentation verify adherence, ensuring system reliability and safety․ Non-compliance can lead to electrical hazards and legal issues․ Always consult local and international standards for specific requirements․

Maintenance and Repair

Regular inspections and timely repairs ensure PVC conduit systems remain safe and functional․ This section covers routine maintenance and fixing damaged conduits for optimal performance․

Regular Maintenance Practices

Regular maintenance is crucial to ensure the longevity and safety of PVC electrical conduit systems․ Inspect conduits for signs of damage, wear, or environmental stress․

- Clean debris and dirt from conduit surfaces to prevent obstruction and moisture buildup․

- Check for cracks, dents, or leaks, especially in underground or exposed installations․

- Verify that all fittings and connections are secure and properly sealed․

- Ensure that conduits remain free from pests or contaminants that could compromise their integrity․

Regularly scheduled inspections and proactive maintenance help prevent system failures and ensure compliance with safety standards and codes․

Repairing Damaged Conduit

Repairing damaged PVC conduit requires careful assessment and precise techniques to restore its integrity․ Start by evaluating the extent of the damage to determine if a partial or full replacement is needed․

- Clean the damaged area thoroughly to remove dirt or debris․

- For minor cracks or splits, use a PVC conduit repair kit with compatible adhesives and fittings․

- Cut out severely damaged sections using a hacksaw or PVC cutter, ensuring smooth, square cuts․

- Deburr the edges to prevent sharp surfaces from damaging wires․

- Join the new section with couplers or connectors, applying primer and solvent cement for a watertight seal․

Always use materials compatible with the existing conduit to maintain system safety and reliability․

Troubleshooting Common Issues

Troubleshooting PVC conduit issues involves identifying leaks, misaligned joints, or improper bends․ Inspect connections, test integrity, and repair or replace damaged sections to ensure system reliability․

- Check for leaks at joints or bends․

- Verify proper alignment and securing of conduit․

- Use appropriate tools for cutting and joining․

Addressing issues promptly prevents further damage and ensures safe electrical operation․

Identifying and Solving Leaks

Leaks in PVC conduit systems often occur at joints or bends due to improper installation or damage․ Inspect connections for gaps or cracks, and use a soapy water solution to detect air leaks․ To fix leaks, clean and re-seal joints with PVC cement and primer, ensuring proper alignment․ For damaged sections, cut out the affected area and replace it with a new conduit piece, securing it with couplers․ After repairs, test the system under pressure to confirm the leak is resolved․ Regular maintenance and inspections can prevent future issues, ensuring long-term reliability and safety of the electrical system․

Fixing Improper Bends or Joints

Improperly bent or joined PVC conduit sections can compromise the integrity of an electrical system․ If a bend is too sharp or misaligned, cut out the damaged section and replace it with a new conduit piece, ensuring proper alignment․ For faulty joints, inspect for insufficient cement or poor primer application․ Clean the area thoroughly, reapply primer, and reconnect using PVC cement․ If a joint is loose, tighten any threaded fittings or replace the coupling․ For heat-related bends, use a heat gun to carefully reshape the conduit without damaging it․ Always test the repaired section under pressure to ensure a leak-free seal․ Proper repair techniques are essential to maintain system reliability and safety․

Proper PVC electrical conduit installation ensures safe, durable, and efficient electrical systems․ By following guidelines and best practices, installers can achieve reliable and long-lasting wiring solutions․

Successful PVC electrical conduit installation begins with proper planning and design, ensuring compliance with local codes and standards․ Cutting conduit accurately with tools like hacksaws or PVC cutters and deburring edges is crucial to prevent wire damage․ Bending requires heat application and proper tools to maintain conduit integrity․ Joining sections involves solvent welding or using couplers, ensuring leak-proof connections․ Testing conduit integrity post-installation is essential to verify system reliability․ Always follow safety protocols and manufacturer guidelines for materials and tools․ Regular maintenance and inspections help extend the lifespan of the conduit system․ By adhering to these practices, installers can ensure safe, efficient, and durable electrical wiring solutions․

Importance of Compliance and Safety

Compliance with local electrical codes and safety standards is paramount in PVC electrical conduit installation․ Adhering to regulations ensures the system’s reliability and safety, preventing hazards like electrical fires or shocks․ Non-compliance can lead to legal penalties, system failures, and increased risk of accidents․ Proper safety practices, such as using personal protective equipment (PPE) and following manufacturer guidelines, protect installers and end-users alike․ Regular inspections and adherence to NEC guidelines further ensure the integrity of the electrical system․ Safety and compliance are not just legal requirements but crucial for safeguarding lives and property, making them the cornerstone of any successful PVC conduit installation project․

Additional Resources

Access comprehensive PVC electrical conduit installation guides and manuals online․ These resources offer detailed step-by-step instructions, safety tips, and compliance standards for successful PVC conduit projects․

Recommended PDF Guides and Manuals

For in-depth guidance, download PVC electrical conduit installation PDF guides from trusted publishers․ These manuals detail step-by-step processes, safety protocols, and compliance standards․ They cover material specifications, such as NEMA TC-2 and TC-3 for conduit and fittings․ Find tutorials on cutting, bending, and joining PVC conduit, along with tips for underground and surface-mounted installations; Resources like the Scepter PVC Systems Manual and National Electric Code (NEC) guidelines ensure installations meet safety and regulatory requirements․ These PDF guides are essential for professionals and DIYers alike, offering comprehensive insights to guarantee efficient and code-compliant PVC conduit projects․